Edible Packaging: India generates nearly 3.5 million tonnes of plastic waste every year, a large portion of which comes from packaging. From food containers to online delivery wrappers, packaging materials are often used once and then discarded. While bans on single-use plastics have been introduced in various states, enforcement remains patchy, and alternatives are either too expensive or not readily available. As the climate crisis intensifies, and oceans and landfills fill with non-degradable waste, there is growing urgency to innovate in the space of sustainable packaging.

This is where the concept of edible packaging becomes especially intriguing. Edible packaging refers to materials made from natural, biodegradable substances — sometimes even consumable — that serve as alternatives to plastic and synthetic films. Imagine eating a snack and consuming the wrapper too, or composting it into the soil within days. Sounds futuristic? It’s already happening across the world. The question is, can India not only adopt this idea but lead it? Given India’s rich agricultural diversity and abundance of crop residues, the country is uniquely positioned to pioneer edible packaging at scale.

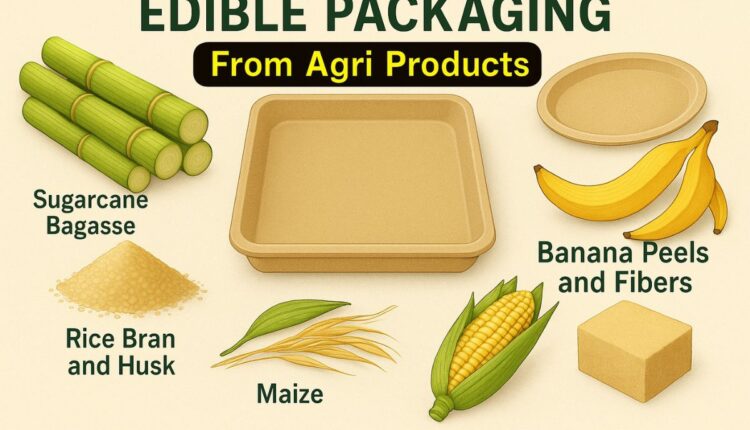

India’s agricultural by-products like sugarcane bagasse, rice husk, banana peels, and corn starch are already being explored in labs and startups for their packaging potential. With the right investment in research, policy, and entrepreneurship, Indian farms could become the foundation of a green packaging revolution. It’s not just an environmental imperative — it’s a rural economic opportunity.

What is Edible Packaging?

At first glance, the term “edible packaging” may sound like a gimmick or science fiction. But in reality, it represents one of the most promising innovations in sustainable packaging technology today. Edible packaging is a type of material made from food-grade substances that can either be eaten safely along with the product or discarded as biodegradable waste. In both cases, it drastically reduces the need for plastic and minimizes environmental impact.

These packaging materials are usually made from natural polymers such as starch, proteins, cellulose, or pectin — substances found in plants, fruits, and dairy. The goal is to create a thin film, sheet, or moulded layer that protects food or other items from moisture, oxygen, and contaminants, just like plastic does — but without the toxic legacy.

There are two key types:

- Edible and Consumable: Wrappers you can eat along with your food. Examples include seaweed-based sachets or milk-protein films used for wrapping cheese.

- Edible and Compostable: These may not taste good or be designed for eating, but they are still safe and biodegradable. Within days or weeks, they break down into the soil without polluting it.

Global examples are already showcasing what’s possible. In Japan, thin sheets of edible starch are used for wrapping candies. In Indonesia, cassava bags from startups like Avani Eco are gaining traction. In the U.S., researchers have developed casein-based films from milk protein that can outperform plastic in food preservation.

What makes this innovation especially relevant for India is that most of these materials can be derived from common crops and by-products found abundantly in Indian farms. Whether it’s banana fibers from Tamil Nadu, sugarcane bagasse from Maharashtra, or corn starch from Punjab, India has no shortage of raw material. This gives the country a significant edge in creating affordable and scalable edible packaging.

In technical terms, edible packaging solutions require careful formulation to ensure they are strong, safe, water-resistant (to a degree), and capable of extending shelf life. This is achieved by blending natural polymers with plasticisers, emulsifiers, and sometimes natural antimicrobial agents. The research and development process is rigorous, but the rewards are promising: lower carbon footprint, fewer plastic imports, and new value chains for Indian agriculture.

Importantly, edible packaging doesn’t need to compete with food demand. Many formulations rely on agricultural waste, by-products, or items not fit for human consumption. For instance, fruit peels, bran, husk, and dairy by-products like whey, which otherwise go unused, can become core ingredients.

As global consumer demand shifts towards cleaner and greener packaging, edible films and bio-based materials are gaining regulatory attention. Countries in the EU and North America are already working on standardising edible packaging safety guidelines. India, with its Make in India and Startup India initiatives, has a real opportunity to join this conversation not just as a user, but as an innovator.

In short, edible packaging is not just a trendy concept — it’s a scientifically viable, environmentally urgent, and economically sensible solution. For a country like India, it could bridge the gap between environmental responsibility and rural entrepreneurship, all while tackling the monumental plastic crisis.

Agricultural By-products That Can Be Used in India

India’s agricultural landscape is not only vast in terms of cultivated area, but also in the diversity of crops it grows. This diversity results in an equally diverse range of agricultural by-products and residues, many of which are traditionally considered waste. However, these by-products are increasingly being viewed as valuable resources — especially for the development of biodegradable and edible packaging materials.

1. Sugarcane Bagasse

Sugarcane bagasse is the fibrous residue left after extracting juice from sugarcane. India, being one of the world’s top producers of sugarcane, generates millions of tonnes of bagasse every year. Bagasse is rich in cellulose and hemicellulose, making it an ideal candidate for moulded packaging trays, plates, and film-like coatings. Today, sugarcane bagasse is already being used in disposable tableware, but advanced research is taking it further into edible film territory. Biodegradable cutlery, edible spoons, and flexible food wraps made from bagasse composites are being tested in Indian institutes.

2. Banana Peels and Fibers

India is the largest producer of bananas in the world. The peel, stalk, and fiber-rich stems of banana plants are typically discarded or used as fodder. These components, however, contain high levels of starch, pectin, and fiber — key ingredients in making biodegradable films. Research in Tamil Nadu and Kerala has explored the extraction of pectin from banana peels to create edible film coatings for bakery products. Banana fiber composites are also gaining attention in both textile and packaging industries.

3. Rice Bran and Husk

As a staple crop, rice creates two major by-products: bran and husk. Rice bran is the outer layer removed during milling and contains proteins and waxes that can be processed into biodegradable sheets. Meanwhile, rice husk, being silica-rich, has excellent insulating properties. Films and containers made from bran-husk composites are now being prototyped in agri-tech labs, especially in West Bengal and Assam. Researchers are even exploring the conversion of husk ash into antimicrobial film layers.

4. Corn Starch and Maize Waste

Corn starch is one of the most widely used ingredients in global bio-packaging solutions, and India has ample maize production to tap into this potential. Starch-based films, foams, and pellets derived from maize can be shaped into bags, wrappers, and cushion packaging. Bioplastic-grade corn starch is already in limited production in parts of Madhya Pradesh and Karnataka. Innovations include edible wrappers for sweets, takeaway containers, and dissolvable pouches.

5. Dairy By-products like Whey

India’s vast dairy sector produces a large volume of whey — a by-product from curdling milk in paneer and cheese production. Whey proteins, particularly casein and whey protein isolate (WPI), have been shown to form edible, transparent, and oxygen-resistant films. These films are ideal for packaging high-fat or aroma-sensitive foods such as cheese, ghee, and snacks. The Amul Research & Development Association has also conducted small-scale pilot studies on whey-based films.

The real breakthrough lies in combining these by-products into composite formulations tailored for specific food types and climates. For example, a mix of banana starch and rice bran could yield a wrapper ideal for packaging dry snacks in humid regions. With the right formulation, India could generate a whole line of region-specific edible packaging solutions based entirely on local agri-waste.

These innovations don’t just solve an environmental problem — they create new markets for farmers, reduce agricultural waste, and stimulate rural economies. In doing so, edible packaging rooted in Indian farms could emerge as a global model of circular, sustainable design.

Indian Research and Startups in Edible/Biodegradable Packaging

India’s growing ecosystem of innovation is beginning to take edible and biodegradable packaging seriously. With increased government backing for startups, a flourishing scientific community, and global pressure to reduce plastic waste, the nation is witnessing a surge in R&D focused on alternative packaging solutions. At the heart of this momentum is a small but growing community of scientists, startups, and entrepreneurs exploring how India’s agricultural resources can be transformed into planet-friendly packaging.

1. Leading Research Institutions

Several of India’s top academic and scientific institutions have made significant progress in this field. The Indian Institute of Technology (IIT) campuses in Delhi, Guwahati, and Kharagpur, along with the Indian Council of Agricultural Research (ICAR) and the Central Institute of Plastics Engineering & Technology (CIPET), are actively working on biodegradable and edible packaging materials. For example, IIT Guwahati researchers have developed films made from seaweed and natural polysaccharides that can degrade within 48 hours when exposed to soil microbes.

Similarly, ICAR’s regional centers in Coimbatore and Ludhiana are conducting experiments using banana starch and rice bran to create edible sheets and coatings. The National Dairy Research Institute (NDRI) is also exploring casein-based films for dairy product packaging.

2. Startups and Innovations

India has seen an explosion of agri-tech and eco-startups in the last five years, many of which are addressing the packaging issue directly. Notable names include:

- Bakey’s (Hyderabad): Produces edible cutlery made from sorghum, wheat, and rice flour.

- EnviGreen (Bangalore): Uses starch and vegetable oils to produce bags that are 100% biodegradable and dissolve in water.

- Ecoware (Delhi): Manufactures compostable packaging using sugarcane residue and other crop waste.

- LeafyWrap: A Delhi-based startup working on edible films derived from jackfruit and mango peel extracts for wrapping dry snacks.

These ventures are not only environmentally driven but also rooted in India’s local agricultural strengths. By using regional crop by-products, they reduce transport costs and promote rural sourcing.

3. Government Support and Policy Landscape

Under the Startup India Mission, the government has created incubation platforms and funding schemes for sustainability-focused entrepreneurs. Similarly, the Atal Innovation Mission is helping academic institutions commercialize packaging innovations through seed funding and partnerships with industry players.

The Food Safety and Standards Authority of India (FSSAI) is also beginning to explore edible packaging regulations, which would be crucial for ensuring safety and acceptance in the food industry. The Bureau of Indian Standards (BIS) is working with researchers to create guidelines for biodegradable material certifications.

4. Collaborative Models

Collaborations between rural farmer producer organizations (FPOs), academic institutions, and local industries are paving the way for decentralized production of biodegradable packaging. These micro-units can process banana fibers, bagasse, and other materials into packaging components, creating employment and reducing supply chain burdens.

In essence, India is not just catching up — it is creating a distinctly Indian model of innovation in the edible packaging sector. This model blends grassroots sourcing, local materials, and scientific rigour, showing how sustainability can emerge organically from a country’s existing agricultural and entrepreneurial DNA.

Benefits of Edible and Biodegradable Packaging

The adoption of edible and biodegradable packaging is not merely a matter of environmental ethics; it presents a multifaceted opportunity for India to address pollution, support farmers, foster rural industries, and align with global sustainability goals. Below are five key areas where these innovations can yield significant benefits:

1. Environmental Impact Reduction

Plastic packaging remains one of the biggest contributors to land and ocean pollution. Edible and biodegradable alternatives break down naturally in a matter of days to weeks, leaving no toxic residue. These materials reduce reliance on petroleum-based plastics and help combat climate change by lowering greenhouse gas emissions during production and degradation. As India aims to meet its sustainability targets under the Paris Agreement, biodegradable packaging provides a low-hanging fruit for meaningful progress.

2. Waste-to-Wealth for Farmers

Agricultural by-products such as banana peels, wheat bran, and sugarcane bagasse are often discarded or underutilized. By converting these into high-value packaging materials, farmers can tap into an additional income stream. This shift not only improves farm economics but also encourages more sustainable farming practices by minimizing waste. Initiatives that link Farmer Producer Organizations (FPOs) with packaging startups can build localized value chains and foster inclusive rural development.

3. Health and Safety Advantages

Conventional plastic packaging, especially single-use types, can leach harmful chemicals into food products. Edible packaging made from food-grade materials is inherently safer for direct contact with consumables. Some formulations can also include natural antimicrobials or antioxidants, extending shelf life and preserving product quality. This is especially valuable in a country like India, where food safety is a major concern and refrigeration infrastructure is limited in rural areas.

4. Economic Opportunities and Job Creation

The development of edible and biodegradable packaging opens up new business models for entrepreneurs and rural communities alike. From processing units in agricultural zones to packaging design and manufacturing hubs, the value chain supports job creation at multiple levels. Skill development in biopolymer formulation, fiber processing, and compostable material manufacturing can provide employment in areas that are otherwise dependent on seasonal agriculture.

5. Brand Value and Export Potential

With the global consumer market increasingly favouring sustainable and eco-conscious brands, Indian products wrapped in biodegradable or edible packaging gain a competitive edge. Exporters in the food, spice, textile, and handicraft sectors can use innovative packaging as a unique selling proposition (USP). This aligns well with India’s push to build global brands under the “Vocal for Local” and “Make in India” initiatives.

In summary, edible and biodegradable packaging offers more than an ecological fix. It has the potential to transform agriculture, boost rural economies, improve public health, and enhance India’s standing in global markets. The key lies in adopting an integrated approach that connects farmers, scientists, businesses, and consumers in a shared mission to turn waste into value and packaging into progress.

Challenges in Scaling Up

While the promise of edible and biodegradable packaging is immense, its journey from lab to large-scale implementation is fraught with obstacles. These challenges span the scientific, economic, regulatory, and behavioral dimensions of India’s packaging and agricultural ecosystem. Addressing them requires coordinated efforts among researchers, policymakers, industry leaders, and the public.

1. Performance and Shelf Life Limitations

One of the most pressing concerns is that edible and biodegradable films often have shorter shelf lives and lower mechanical strength compared to plastic. They may not always offer the same level of moisture resistance, oxygen barrier protection, or durability, especially under extreme temperatures and humidity. This limits their application for packaging perishable or moisture-sensitive goods, unless additional coatings or layers are added—which can increase costs.

2. Cost and Price Competitiveness

Despite using agricultural waste as a base, the processing of bio-based packaging materials requires specific technologies, temperature controls, and chemical formulations that can drive up production costs. At present, most edible packaging solutions are more expensive than conventional plastic, making them less attractive to small businesses and budget-conscious consumers. Economies of scale are crucial, but difficult to achieve without substantial market adoption or government subsidies.

3. Regulatory and Safety Frameworks

India currently lacks a dedicated regulatory framework for edible packaging. Questions remain about permissible ingredients, food contact safety, hygiene standards, and labelling. The Food Safety and Standards Authority of India (FSSAI) has yet to develop clear guidelines, which makes it difficult for startups and manufacturers to navigate compliance. Without standardization, consumer trust and market penetration remain limited.

4. Infrastructure and Logistics

Creating a viable edible packaging industry requires more than just raw material supply. It calls for a robust supply chain—from collection and preprocessing of agricultural by-products to centralized or decentralized manufacturing hubs. Cold chain logistics may be necessary to store sensitive formulations. Many rural regions still lack access to the required infrastructure or power supply, which slows down the scalability of local production units.

5. Consumer Awareness and Behaviour Change

Even the most innovative packaging will fail if it isn’t accepted by the end user. In India, where cost sensitivity and cultural food preferences vary widely, consumers may be hesitant to eat packaging or trust its safety. Awareness campaigns are necessary to communicate the benefits, address misconceptions, and normalise edible and compostable packaging. Retailers also need to be educated about storage, handling, and pricing to ensure smooth adoption.

While these challenges are real, they are not insurmountable. In fact, they point toward the need for systemic support: subsidies to level the playing field, public-private partnerships for R&D, pilot programs in select markets, and grassroots innovation in rural communities. By tackling these hurdles strategically, India can position itself not only as a producer of sustainable packaging, but as a leader in rethinking packaging itself—from being a waste product to becoming part of the product experience.

Vision for the Future: How Farms Could Fuel the Green Packaging Industry

To unlock the full potential of edible and biodegradable packaging, India must move beyond pilot projects and fragmented innovations. It needs a national vision that connects its agricultural base with research, industry, and consumer markets in a cohesive and scalable manner. This vision can transform the country from being a high plastic consumer into a global leader in sustainable packaging.

1. Integrating Agri-Processing with Packaging Production

The first step is to establish local hubs where agricultural residues can be efficiently processed into packaging-grade materials. These hubs could be part of existing food parks or Farmer Producer Organization (FPO) clusters. By co-locating raw material collection, preprocessing, and packaging manufacturing, logistics costs can be minimized and rural employment maximized. These hubs can specialize based on regional crop availability—banana stem in Tamil Nadu, wheat bran in Uttar Pradesh, or rice husk in Odisha.

2. Farmer Cooperatives as Stakeholders

For the packaging revolution to be inclusive and sustainable, it must engage farmers not just as suppliers but as stakeholders. Cooperatives can be empowered with equipment, training, and profit-sharing models to become primary contributors to the value chain. Government schemes such as PM-FME (Formalization of Micro Food Processing Enterprises) and NABARD support can be redirected or expanded to include biodegradable packaging as a key rural enterprise opportunity.

3. Policy Push and Public Incentives

India’s central and state governments can play a catalytic role by offering targeted incentives to bio-packaging startups and buyers. Tax exemptions, research grants, procurement mandates (especially for government-run mid-day meals, defense rations, and railways), and carbon credits could significantly boost the industry’s commercial viability. Mandatory biodegradable packaging for organic or export-grade produce could be another bold step.

4. CSR, NGO, and Global Partnerships

Corporate social responsibility (CSR) programs can adopt edible packaging innovations under environmental and rural development initiatives. NGOs working in climate adaptation, women’s livelihood, or zero waste can also partner with agri-entrepreneurs to scale pilot projects. India could further engage in global innovation exchanges, joining hands with countries like Indonesia, Brazil, and Kenya to co-develop scalable technologies.

5. Building Awareness and Capacity

The success of any large-scale transformation hinges on public understanding. Awareness campaigns in local languages, school education modules, and influencer-driven social media efforts can make biodegradable packaging aspirational. Simultaneously, training programs at Krishi Vigyan Kendras (KVKs), polytechnics, and ITIs can upskill rural youth in packaging design, bio-material science, and production management.

In essence, the future of packaging need not be synthetic. It can be local, circular, and rooted in the fields. With political will, public awareness, and private enterprise aligned, edible and biodegradable packaging can move from niche to norm. In doing so, India will not only clean up its streets and waterways, but also empower its villages to become champions of a truly green industrial revolution.

From Farm Waste to Future Wrappers

India’s edible packaging potential lies at the intersection of its agricultural richness and its urgent environmental needs. With innovation, collaboration, and policy support, what we now see as farm waste can become the raw material for a greener, cleaner future. If scaled wisely, edible packaging won’t just reduce plastic pollution—it will empower rural communities, add value to crops, and place India at the forefront of sustainable global innovation. The wrapper of tomorrow could come from the field next door.

Contact us – If farmers want to share any valuable information or experiences related to farming, they can connect with us via phone or WhatsApp at 9599273766 or you can write to us at “kisanofindia.mail@gmail.com”. Through Kisan of India, we will convey your message to the people, because we believe that if the farmers are advanced then the country is happy.

You can connect with Kisan of India on Facebook, Twitter, and WhatsApp and Subscribe to our YouTube channel.